Principles and benefits of traceability

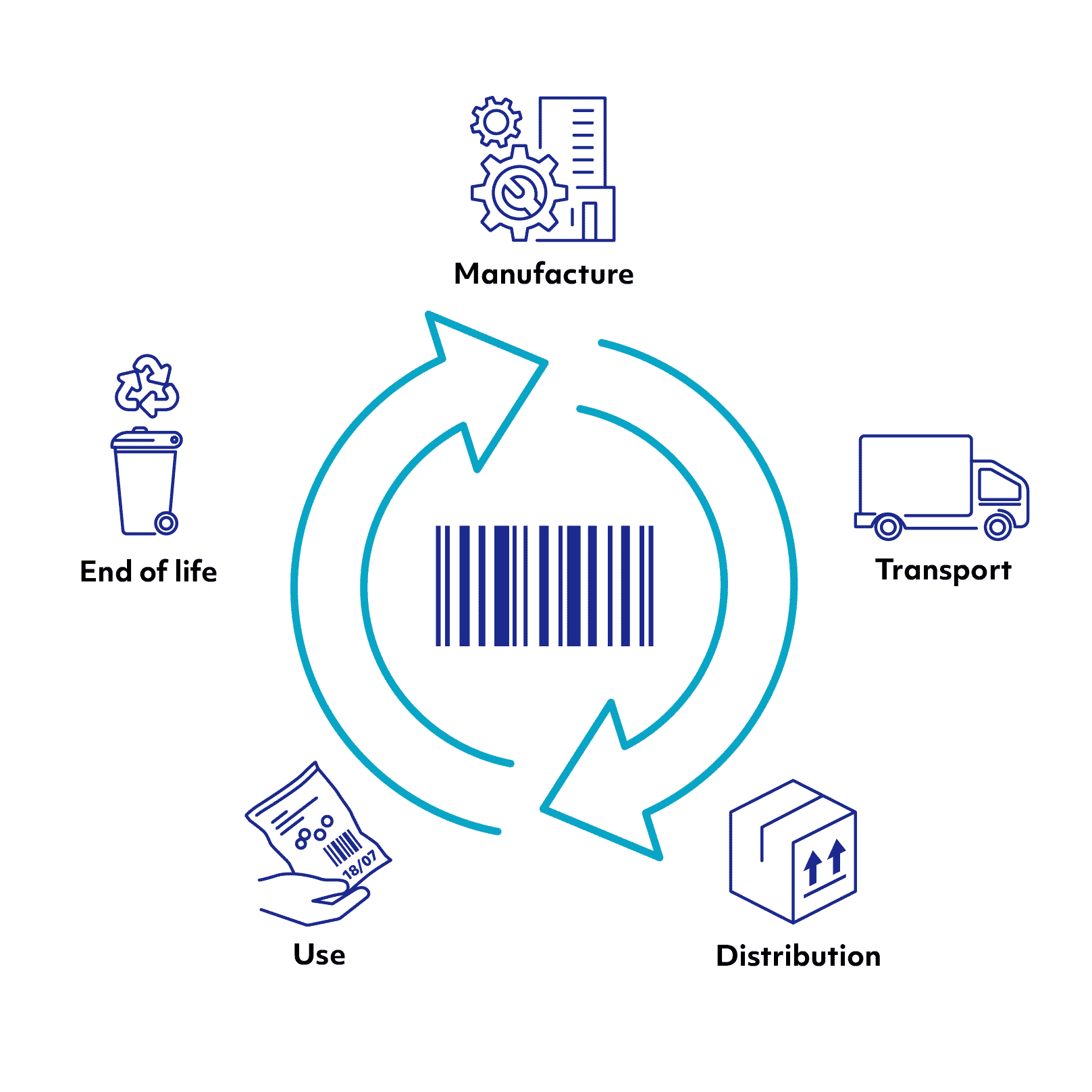

Traceability is the ability to track each event in a product’s life cycle (from manufacture to use) with unique identification data.

These data serve to guarantee product compliance and quality. This coded information attached to a product or service, allows each link in the chain to have access to up-to-date data. In addition to promoting digitalisation, product tracking facilitates logistical flows and guarantees a degree of security and transparency of the information transmitted.

This identification and traceability information is the link between the product and all stakeholders in its life cycle: the production line operator, the order picker, the carrier, the inventory manager, the receptionist, the store salesperson and the end user.

This overview is a means of risk prevention and safety for consumers.

The most common traceability tool is the bar code because it allows a universal reading of the information attached to it.

Current Regulations

Beyond the strategic aspect for manufacturers and logistics chain stakeholders, product traceability is sometimes imposed by regulations to ensure the safety of goods and people.

In the United States there is a unique identification system (UDI) for the traceability of medical devices. This system makes it possible to guarantee the origin of the product, to avoid the use of counterfeits and thus to ensure the quality of patient treatment. First entered into force in the United States, the UDI system has also been adopted by the European Union.

In China, strict regulations on food traceability have emerged to prevent any health risks. The Chinese government has implemented a very demanding food chain traceability system for all the industries concerned.

At the industrial scale, the motor industry imposes stringent traceability, particularly for certain sensitive components (engines, brakes, steering). To avoid the risk of failure and ensure the safety of people, the traceability of auto parts is essential at each step in the vehicle manufacturing process and throughout its life cycle.

These examples illustrate the need to trace an entire logistics chain and the means implemented by the institutions to ensure product quality and consumer safety. According to the regulations in force, traceability must also ensure the reliability and legibility of the information on the life cycle of the products, along with their accessibility.

Different types of traceability

Pharmaceutical product traceability:

Pharmaceutical product traceability is a strategic issue in terms of public health because it allows the origin of a health problem to be traced through recorded information. In the USA and Europe, every medical device enters a traceability process from its manufacture in the laboratory until its use, or even its destruction.

The Unique Device Identifier (UDI) records a very large amount of identification and traceability data, such as:

- dosage

- batch number

- expiry date

- dosage form

- etc.

This means of identification also makes it possible to prevent the counterfeiting of drugs or medical devices. It therefore guarantees the use of original products and limits the sale of uncontrolled products.

Traceability for care:

In hospitals, traceability is increasingly present to secure the patient’s treatment. Bar code-base care traceability makes it possible to inform the medical personnel of the patient’s health and care previously given, as well as the medical history of the patient.

By increasing the volume of medical information, it prevents the risk of errors or of inappropriate or risky treatment.

Food product traceability:

Food product traceability allows consumers, distributors and manufacturers to better control the origin, composition and conformity of products.

With extremely advanced food traceability systems (assisted by a blockchain system), distributors control and secure their supplies, while consumers have access to more information to improve their choices.

Traceability in logistics:

Logistics traceability aims to ensure product testing, monitoring and delivery. With a simple bar code, all supply chain stakeholders’ access up-to-date identification and traceability information to monitor the product at each stage of its life cycle.

Thanks to logistics traceability, supply chain flows are simplified and accelerated, bringing real added value for consumers and manufacturers.

Thermal Transfer technology is the most widely used for printing composition and worldwide tracking information.

inkanto Thermal Transfer ribbons meet all these needs and constraints, such as print durability, printed information legibility, fineness of characters, etc.

Traceability solutions provided by ARMOR-IIMAK

Thermal Transfer is a reliable, robust and competitive printing technology for marking bar code traceability data, batch or serial numbers, etc.

The range of inkanto Thermal Transfer ribbons makes it possible to meet all the requirements for printing traceability labels by providing:

Durability:

Secure traceability data by printing with inks capable of withstanding the most demanding environments (handling, friction, heat, solvents) or very long life cycles.

Print sharpness:

With inkanto ribbons, small characters or small bar codes are 100% readable by optical readers.

Versatility of print media:

Whatever the material of the traceability label, there is an inkanto ribbon available for perfect printing (rough, coated, synthetic, plastic, textile papers, etc.)

Competitiveness:

Some ribbons are specifically designed for traceability applications where cost is the primary criterion.

Printer compatibility:

Several tens of thousands of possible ribbon configurations to accommodate all Flat Head and Near Edge printers on the market.

Certifications:

The ribbons are certified according to the main regulatory requirements in force: food industry (food contact), electrical/electronic (RoHS, Halogen), REACH standard, etc.

Comprehensive product range:

There is a dedicated ribbon for each application to cover 99% of traceability labels.