How to print your

traceability data

with confidence

A wide range of Thermal Transfer ribbons to cover every printing challenges

ARMOR-IIMAK identity

Say hello to inkanto !

Our brand of ribbons packaged with unique benefits

I could not be more pleased with the process effort that the ARMOR-IIMAK team put in. Communication is clear, I was provided with data reports showing clear improved results, and could select from a range of products that would best fit my end-user needs. Job well done!

ARMOR-IIMAK: from pioneer to leader

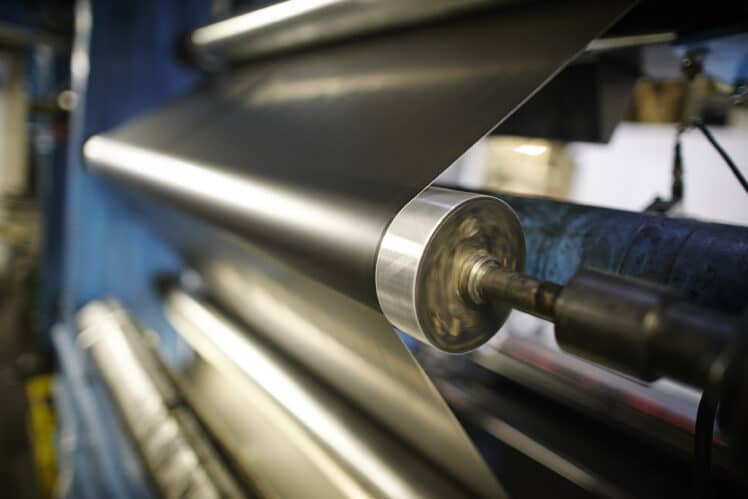

- 1000Number of meters of film coated each minute on our most newest production line

- 420 000Daily ribbon slitting capacity to support our customers’ development

- 12%Less plastic on new ribbons thanks to thinner PET film

- 130People dedicated to daily customer care

- 1700Number of employees dedicated to Thermal Transfer technology